Braided Polypropylene Rope Breaking Strength

Safety factor is a measure of the load a rope should be rated to handle a given project.

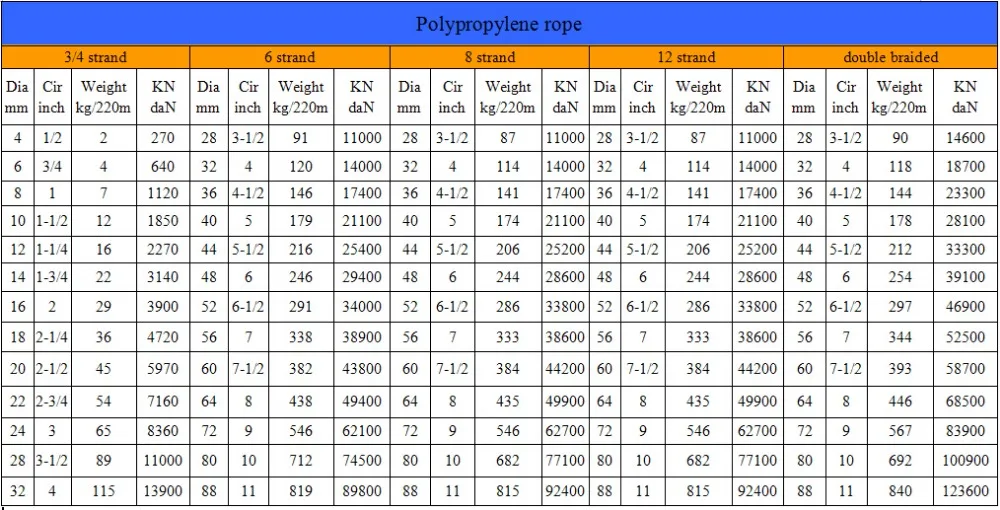

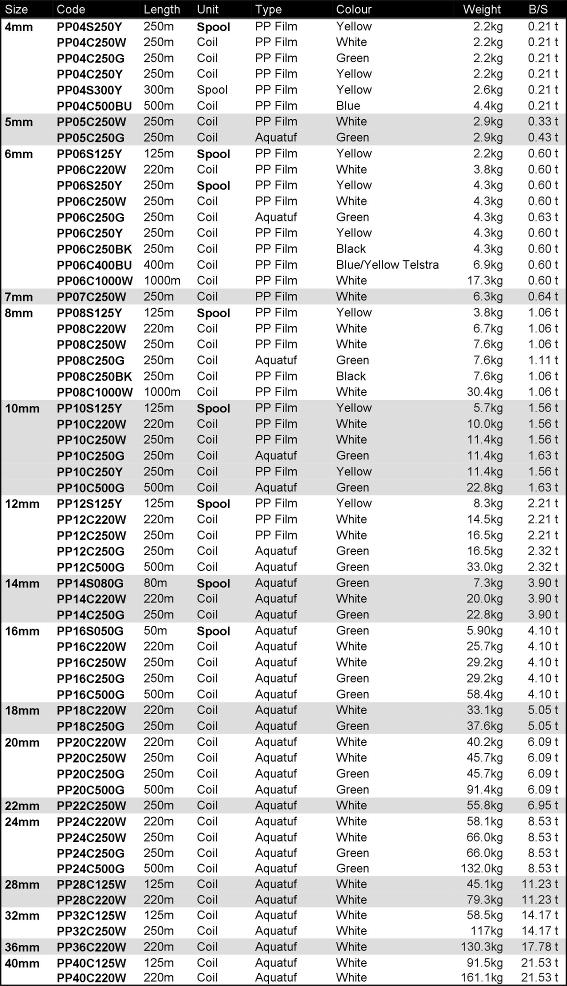

Braided polypropylene rope breaking strength. Polypropylene fiber rope strength polypropylene fiber 3 strand and 8 strand rope minimum breaking strength and safe load. Spilt and flat film yarn twisted rope monofilament twisted pp rope multifilament can cut to 1m 2m 5m long pcs. Shackles safe loads safe loads of shackles. Breaking strength braided twisted 100 polypropylene twine pp rope for packing.

Polypropylene twine baling twine polypropylene gardening twine. These are the listed breaking strengths of each rope type and size. Polypropylene rope is made of from monofilament or film polypropylene. Minimum breaking strength and safe load of polypropylene rope are indicated below.

Rope specs amsteel blue dyneema as 78 single braid breaking strength. Standard working loads on sheets halyards and control lines are usually calculated at 20 of a line s breaking strength. Breaking strength is the amount of weight a rope can bear without breaking. Produce the belt or rope and bags packaging agriculture material virgin pp pp rope specs.

The strength of a rope determines how heavy a load it can handle. Always consult the manufacturer s instructions for handling heavy loads. Sisal rope strength sisal rope 3 strand minimum breaking. Polyester rope strength polyester 3 strand and 8 strand rope minimum breaking strength and safe load.

It is recommended not to exceed 1 3 3 1 design factor of the rope s strength to maintain a useful service life. Rope dia mm 220m coil weight kgs approx breaking strain kgs 4mm. Greater line holding working loads are achieved by increasing the diameter of the line. Diamond braid nylon rope 3 16 5mm by 100feet paracord general purpose utility rope polypropylene rope high strength all purpose braided utility flag line rope for indoor or outdoor use green 4 5 out of 5 stars 147.

Polyester and nylon double braid 3 strand twisted or polypropylene manila this rope strength guide helps determine diameter tensile and working load of the various ropes specific for your use. Match the diameter of the line to the application.

%2C445%2C291%2C400%2C400%2Carial%2C12%2C4%2C0%2C0%2C5_SCLZZZZZZZ_.jpg)